Selecting the appropriate bolt finish is a crucial aspect of fastener selection in various industries, from construction to manufacturing. Bolt finishes not only enhance the appearance of bolts but also provide essential protection against corrosion and other environmental factors. In this comprehensive guide, we will explore the factors to consider when choosing the right bolt finish, provide charts illustrating specifications for different finishes, and outline common applications for each finish.

Factors to Consider When Choosing Bolt Finish

When deciding on the right bolt finish for your application, several key factors come into play:

Corrosion Resistance:

- Consider the environment in which the bolts will be used. If they will be exposed to moisture, chemicals, or saltwater, corrosion resistance is crucial.

- Stainless steel and galvanized finishes are known for their exceptional corrosion resistance.

Aesthetic Requirements:

- Depending on the application, aesthetics may be a consideration. In architectural and decorative applications, the appearance of the bolts matters.

- Polished, chrome, or nickel finishes are often chosen for their attractive appearance.

Temperature Tolerance:

- Some applications involve extreme temperatures, either high or low. Ensure the chosen finish can withstand these temperature variations.

- Stainless steel, nickel, and zinc-nickel finishes often offer good temperature tolerance.

Cost:

- Cost can be a significant factor. Some finishes are more expensive than others.

- Consider your budget and the long-term cost-effectiveness of the chosen finish in terms of maintenance and replacement.

Environmental Impact:

- Be mindful of the environmental impact of your choice. Some finishes may contain hazardous materials or require specific disposal methods.

- Environmentally friendly finishes, such as zinc, may be preferred in some cases.

Bolt Finish Chart

To assist in your decision-making process, here is a chart illustrating specifications for different bolt finishes, along with common applications for each finish:

Table 1: Bolt Finish Specifications and Common Applications

Understanding Bolt Finish Types

Zinc (Zn):- Consider the environment in which the bolts will be used. If they will be exposed to moisture, chemicals, or saltwater, corrosion resistance is crucial.

- Stainless steel and galvanized finishes are known for their exceptional corrosion resistance.

Zinc-Nickel (ZnNi):

- Depending on the application, aesthetics may be a consideration. In architectural and decorative applications, the appearance of the bolts matters.

- Polished, chrome, or nickel finishes are often chosen for their attractive appearance.

Cadmium (Cd):

- Some applications involve extreme temperatures, either high or low. Ensure the chosen finish can withstand these temperature variations.

- Stainless steel, nickel, and zinc-nickel finishes often offer good temperature tolerance.

Stainless Steel (SS):

- Cost can be a significant factor. Some finishes are more expensive than others.

- Consider your budget and the long-term cost-effectiveness of the chosen finish in terms of maintenance and replacement.

Chrome (Cr):

- Be mindful of the environmental impact of your choice. Some finishes may contain hazardous materials or require specific disposal methods.

- Environmentally friendly finishes, such as zinc, may be preferred in some cases.

Nickel (Ni):

- Be mindful of the environmental impact of your choice. Some finishes may contain hazardous materials or require specific disposal methods.

- Environmentally friendly finishes, such as zinc, may be preferred in some cases.

Black Oxide (BlkOx):

- Be mindful of the environmental impact of your choice. Some finishes may contain hazardous materials or require specific disposal methods.

- Environmentally friendly finishes, such as zinc, may be preferred in some cases.

Galvanized (Galv):

- Be mindful of the environmental impact of your choice. Some finishes may contain hazardous materials or require specific disposal methods.

- Environmentally friendly finishes, such as zinc, may be preferred in some cases.

Phosphate (Phos):

- Be mindful of the environmental impact of your choice. Some finishes may contain hazardous materials or require specific disposal methods.

- Environmentally friendly finishes, such as zinc, may be preferred in some cases.

Factors to Consider When Choosing Bolt Finish

When deciding on the right bolt finish for your application, several key factors come into play:

Corrosion Resistance:

- Consider the environment in which the bolts will be used. If they will be exposed to moisture, chemicals, or saltwater, corrosion resistance is crucial.

- Stainless steel and galvanized finishes are known for their exceptional corrosion resistance.

Aesthetic Requirements:

- Depending on the application, aesthetics may be a consideration. In architectural and decorative applications, the appearance of the bolts matters.

- Polished, chrome, or nickel finishes are often chosen for their attractive appearance.

Temperature Tolerance:

- Some applications involve extreme temperatures, either high or low. Ensure the chosen finish can withstand these temperature variations.

- Stainless steel, nickel, and zinc-nickel finishes often offer good temperature tolerance.

Cost:

- Cost can be a significant factor. Some finishes are more expensive than others.

- Consider your budget and the long-term cost-effectiveness of the chosen finish in terms of maintenance and replacement.

Environmental Impact:

- Be mindful of the environmental impact of your choice. Some finishes may contain hazardous materials or require specific disposal methods.

- Environmentally friendly finishes, such as zinc, may be preferred in some cases.

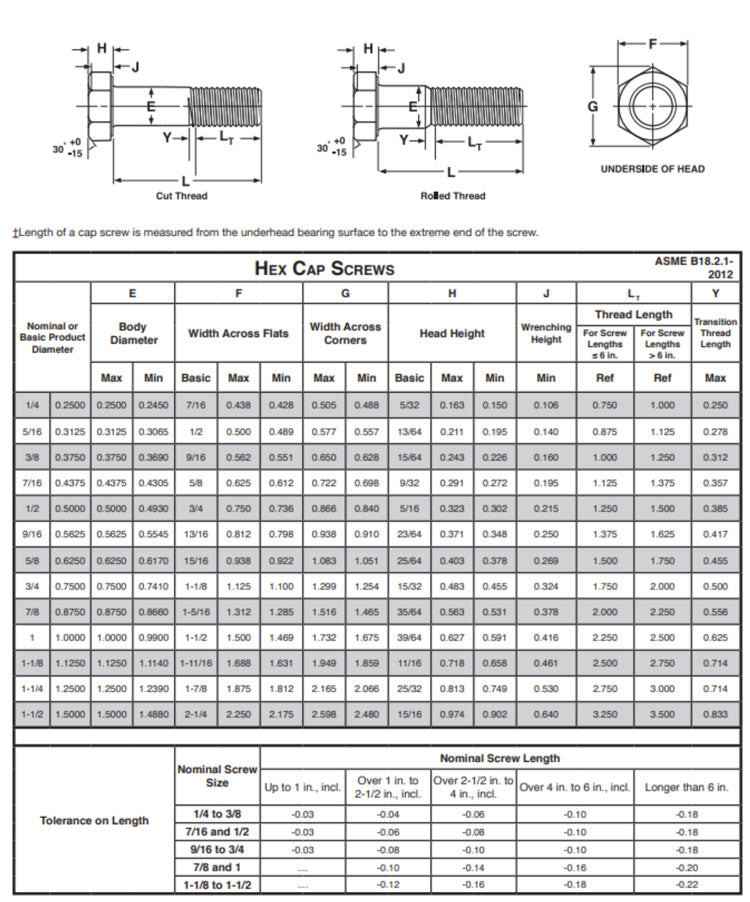

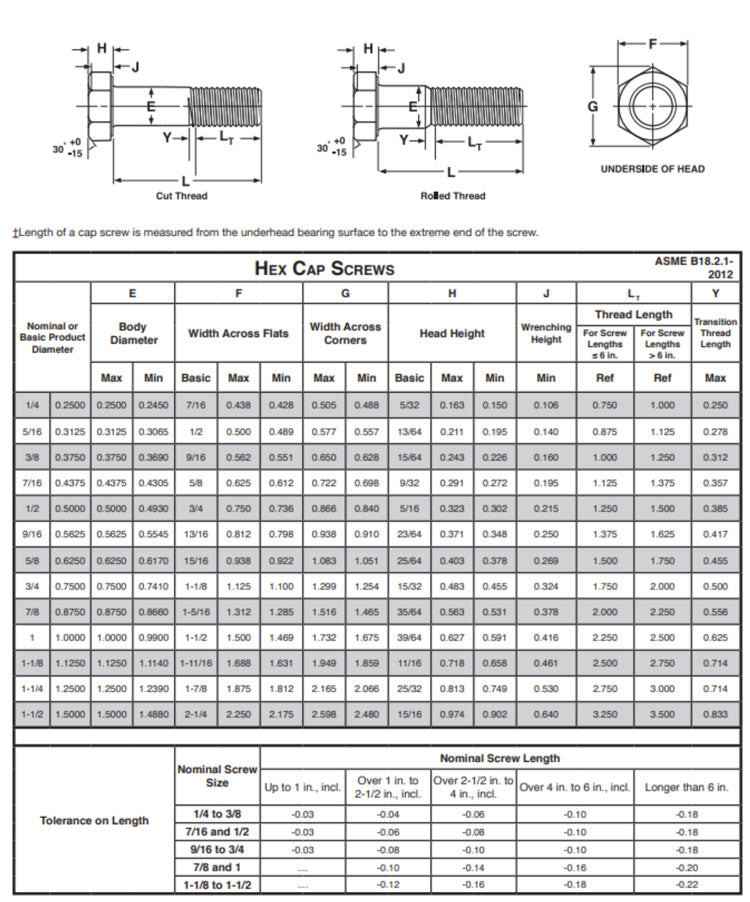

Hex Cap Screw Specifications