Quick Facts

When it comes to secure and reliable fastening solutions, hex cap screws stand as a cornerstone in various industries. These screws, recognized by their hexagonal heads and threaded shafts, are celebrated for their versatility, strength, and ease of use.

Hex cap screws, also known as hex head screws or used interchangeably with hex bolts, are threaded fasteners characterized by their hexagonal head design. This head shape allows for easy and efficient tightening using a wrench or socket, making them a preferred choice for applications where torque is a critical factor. The threaded shaft of the hex cap screw ensures a secure and lasting connection between components.

The Difference Between Hex Cap Screws and Hex Bolts

These terms are often used interchangeably in the field when they are two different bolts with different properties. The most basic difference between a cap screw and a hex bolt is the way in which they are installed. Technically, a bolt is installed by turning a nut to tighten the fastener while a cap screw is installed by turning the head of the bolt to assemble and tighten. Therefore, cap screws are often threaded into a tapped hole on pieces of equipment or machinery.

So how do you know which one you use and/or need? A good rule-of-thumb is that if you are getting bolts that are easily found off-the-shelf through your supplier, they’re likely to be hex head cap screws. Common-sized cap screws are made through a cold-heading process in large runs while hex bolts are made through hot-forging, a more intensive and expensive manufacturing process. To the untrained eye, both will look the same in many applications, and both may be equally appropriate. If your application does not require one or the other, you’ll be better off with cap screws.

Hex Cap Screws

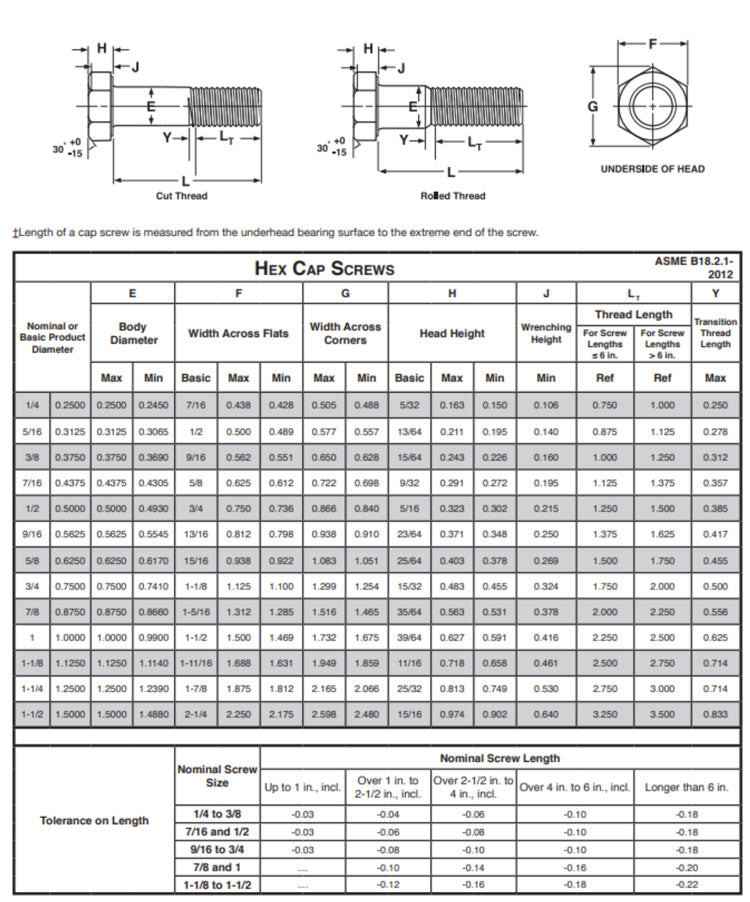

- Flat washer facing under the head that meet specific tolerances (ASME B18.2.1)

- Chamfered end

- Typically manufactured through a cold-heading process in large runs of standard sizes

- Common specs: ASTM A449, SAW J429 Grade 2, 5, 8

Hex Bolts

- A die seam across the bearing surface is acceptable

- Flat end

- Typically manufactured by a more expensive hot-forging process

- Common specs: ASTM A307A, A354, F1554

Where are hex cap screws used?

Hex cap screws find a multitude of applications across industries due to their reliability and strength. Some of the most common uses include:

Construction and Manufacturing: In construction and manufacturing, hex cap screws are utilized to fasten structural components, machinery parts, and equipment. They ensure secure connections that can withstand heavy loads and stress.

Automotive and Aerospace: Both the automotive and aerospace industries rely on hex cap screws to hold together critical components, from engine parts to aircraft structures. The secure fastening provided by these screws is essential for maintaining safety and operational efficiency.

Machinery and Equipment: Hex cap screws are found in various machinery and equipment assemblies, ensuring stability and reliability. They are used in everything from engines to conveyor systems, where consistent torque and secure connections are vital.

Electronics and Electrical Equipment: Even in electronics, hex cap screws play a role. They are used to secure components within enclosures and equipment housings, ensuring proper protection and stability for sensitive electronics.

DIY Projects and Home Improvement: In the realm of DIY projects and home improvement, hex cap screws are utilized to assemble furniture, install shelves, and create structures. Their straightforward design and compatibility with common tools make them a popular choice for homeowners and hobbyists.

Hex Cap Screw Specifications