Screws: Unraveling Their World

Screws are one of those ubiquitous inventions that we encounter daily but often overlook. While they may seem like simple pieces of hardware, they are indispensable in various aspects of our lives, from assembling furniture to constructing skyscrapers. Most applications can use any type of screw, and choosing the right screw for your project mostly comes down to preference, investment you want to make, and time you want to save.

To explore which one you’d like to use, it’s helpful to be aware of how a screw is structured:

Screws vs. Bolts: What’s the difference? ➔

To understand the significance of screws, we first need to differentiate them from bolts. Although the terms "screw" and "bolt" are sometimes used interchangeably, there are distinct characteristics that set them apart.

- Threads. The most noticeable difference is in the threading. Screws have helical threads, allowing them to engage with materials and create a secure hold when rotated. In contrast, bolts typically have threads only near the top, with the unthreaded portion designed to pass through holes in the objects being joined.1. Threads. The most noticeable difference is in the threading. Screws have helical threads, allowing them to engage with materials and create a secure hold when rotated. In contrast, bolts typically have threads only near the top, with the unthreaded portion designed to pass through holes in the objects being joined.

- Applications. Screws are primarily used to join or fasten materials together, often by tapping them into pre-made holes (but no threads). Their threading enables them to pull materials tightly together, making them ideal for tasks like assembling furniture, attaching hinges to doors, or securing electrical outlets. Bolts, on the other hand, are generally used with nuts and are better suited for applications where a through-hole is available or to match pre-threaded holes, such as construction and automotive assembly.

- Head Type. Screws often have a variety of head types, including Phillips, flathead, hex, and Torx, among others, designed for specific applications. Bolt heads are typically larger and more limited in their variety.

When do you use a screw vs. a bolt?➔

The choice between using a screw or a bolt depends on several factors, including the specific application, materials being joined, and the desired outcome. Here are some guidelines to help you determine when to use a screw instead of a bolt:

Materials Being Joined

- Wood: Screws are commonly used in woodworking because their threads can grip wood fibers effectively, creating a secure connection. In contrast, bolts are not as well-suited for wood applications unless combined with nuts and washers.

- Metal: Bolts are typically preferred when joining metal components because they can handle higher loads and provide a stronger connection. Screws may be used for lighter-duty metal applications or when self-tapping screws are required to create threads in metal.

Application Type

- Permanent vs. Removable: Screws are often used in applications where the connection may need to be removed or adjusted later, such as assembling furniture, electronic devices, or appliances. Bolts are generally chosen for permanent connections or those where regular disassembly is not required.

- Through-Hole vs. Blind Hole: If you have a hole that goes completely through both materials you are joining, a bolt with a nut on the opposite side is a common choice. Screws are typically used when you have a blind hole (a hole that doesn't go all the way through) and need the screw's threads to engage with the material.

Load and Strength Requirements

- Heavy Loads: Bolts are preferred when joining components that will experience significant loads or stress, such as in construction, automotive, or structural applications.

- Light to Moderate Loads: Screws are suitable for applications with lighter to moderate loads, such as securing electrical outlets, attaching door hinges, or assembling lightweight furniture.

Ease of Installation

- Screws: Screws are easier to install compared to bolts, as they do not require a separate nut and can be driven directly into a pre-drilled hole. This ease of installation makes screws a popular choice for DIY projects.

- Bolts: Bolts typically require more components (bolts, nuts, washers) and often need more tools for assembly, making them better suited for industrial or professional applications.

Specific Screw Features:

- Self-Tapping Screws: These screws have a cutting edge and can create their threads as they are driven into the material. They are commonly used in applications where no pre-existing threads are present, such as in sheet metal or plastic.

- Threaded Inserts: Screws can be used with threaded inserts to provide a strong and reusable threaded connection in materials like wood or plastic. This expands the utility of screws in various applications.

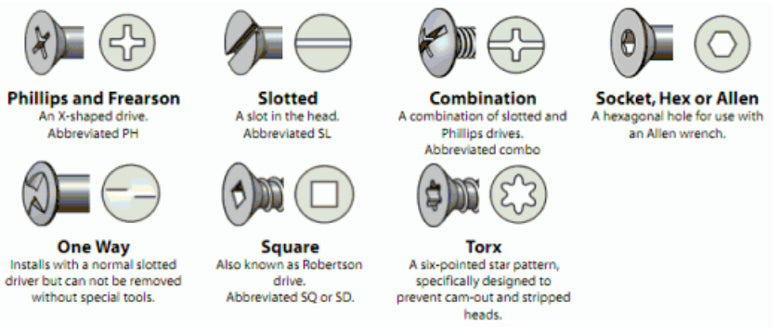

What kind of drive can I choose from?➔

There are a number of drives to choose from. The most popular are: Phillips or None (especially with hex or hex washer heads).

What kind of head can I choose from?➔

Please see the many head options below. The most common head types are: flat, pan, hex, and hex washer.

What kind of tip can I choose from?➔

Please find most drill tip types below. The most commonly used tips are Type A, Type AB, Type F and Drill Point.